@ATORelays

In many industrial environments, system failures are often traced back to a small number of overlooked components. Relays are one of them. While they rarely attract attention during system design, they frequently determine how faults propagate, how quickly protection activates, and whether equipment recovers or shuts down safely. Choosing an industrial relay supplier is therefore less about catalog breadth and more about how relay behavior aligns with real operating stress.

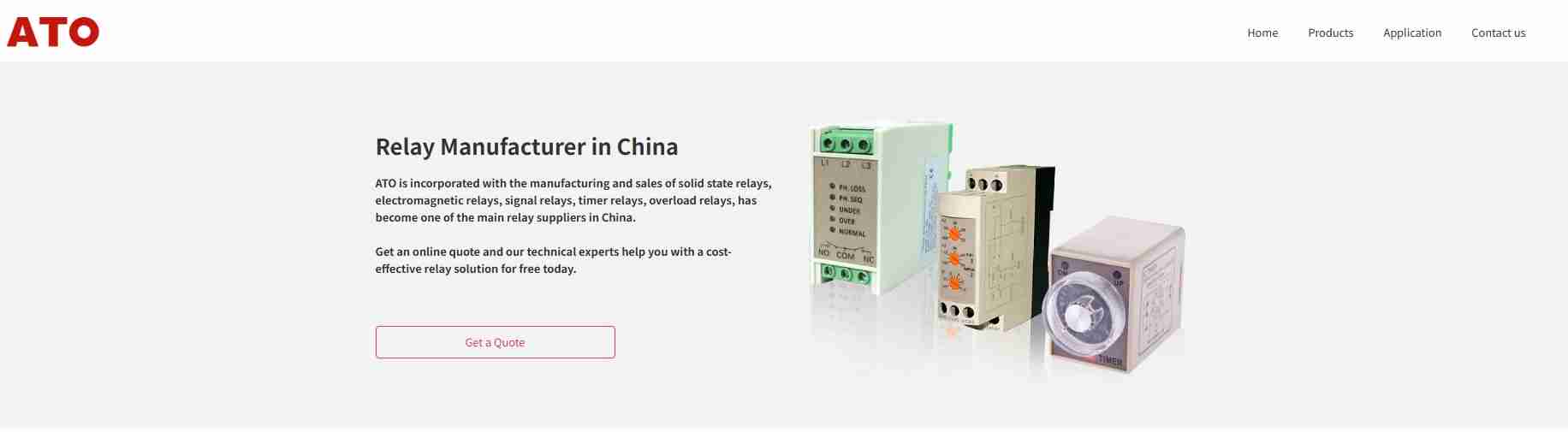

Different operating conditions demand different relay technologies. In applications where switching frequency is high or electrical noise must be minimized, solid state relay solutions are commonly selected to eliminate mechanical wear and contact bounce. Conversely, electromagnetic relay designs remain essential in circuits that require visible isolation, fault tolerance, and compatibility with legacy control architectures. ATOrelays supplies both categories, allowing engineers to select industrial relay products based on load characteristics rather than convenience or habit.

Control logic and protection functions introduce additional requirements. Signal relay and control relay products are widely used in PLC interfaces, sensor circuits, and automation panels, where consistent response and long-term stability are critical. Timer relay units provide reliable sequencing and delay control without increasing software complexity, while monitoring relay and thermal overload relay solutions act as safeguards against phase loss, voltage imbalance, or sustained overcurrent conditions. These protective layers often prevent minor anomalies from escalating into system-wide failures.

Industrial installations rarely rely on a single relay type. Motor control centers, for example, may integrate power relay components with overload protection, while modular relay module assemblies simplify wiring and reduce panel footprint. ATOrelays’ product lineup supports this mixed deployment model, enabling compatible relay selection across power, control, and monitoring functions without introducing unnecessary variation or sourcing complexity.

From a lifecycle perspective, relay performance must be evaluated over time, not at installation. Heat accumulation, load cycling, and contact degradation all affect service life and maintenance schedules. By offering industrial relay solutions designed for continuous-duty operation and predictable switching behavior, ATOrelays helps system designers and maintenance teams reduce unplanned downtime and standardize replacement strategies across multiple installations.

As an industrial relay supplier serving automation equipment builders, system integrators, and maintenance-driven operations, ATOrelays positions its products as functional building blocks within larger electrical systems. The focus remains on dependable switching, clear signaling, and protective response—ensuring relays contribute to system resilience rather than becoming hidden points of failure.